GET A QUOTE

A disposable thermoforming machine, also known as a multi-station thermoforming machine, typically consists of three or four stations. Four-station thermoforming machines differ from three-station models by including an additional punching station, commonly used for producing items such as fruit trays and seedling boxes. Four-station machines are also more versatile. For products that do not require punching, they can still be used by equipping molds for just three stations: forming, cutting, and stacking.

The 780 * 650MM is the largest molding layout thermoforming machine available from Sinoplast. To increase output, we focus not only on improving production speed but also on expanding the number of mold cavities. During normal production, our equipment can achieve a speed of 35-40 molds per minute.

Furthermore, our food container thermoforming machines are equipped with safety protection features. If the machine operates too quickly and the workstation is unable to keep up, the system will automatically stop to prevent damage. After stopping, the operator can easily use the reset button on the touch screen to restore each workstation to its initial position and reduce the production speed before restarting.

As a supplier of high-quality plastic thermoforming equipment, Sinoplast has received unanimous praise from customers in a fiercely competitive environment. We have years of experience and capability in thermoforming, mature process flow, and provide various technical solutions. According to the strategic goals set by the company, we adhere to consistent quality standards in all processes. We are committed to continuously improving our quality and management system, whether in design, research and development, production, installation, or service.

|

Model |

SPM-780E |

SPM-780D |

SPB-780E |

SPB-780D |

|

Station Number |

3 |

4 |

3 |

4 |

|

Max.Forming Area |

780*540MM |

780*650MM |

||

|

Max.Forming Depth |

105MM(Can be customized) |

|||

|

Suitable Material |

PP/PS/PET |

|||

|

Sheet Width |

550-820MM |

|||

|

Material Thickness Range |

0.15-2MM |

|||

|

Max. Sheet Roll Dia. |

1200MM |

|||

|

Running Speed |

35-40Cycles/min |

|||

|

Forming Station Power |

Servo Motor 7 KW*2 pcs |

|||

|

Forming station stretching |

Servo Motor 3.5 KW |

|||

|

Hole Punching Station Power |

NONE |

Servo Motor 14 KW |

NONE |

Servo Motor 14 KW |

|

Cutting Station Power |

Servo Motor 7 KW*2 pcs |

|||

|

Stacking Station Power |

Servo Motor 3.5 KW |

|||

|

Sheet Feeding Method |

Servo Motor 3.5 KW |

|||

|

Air Consumption/Air Pressure |

3m3/min,0.6-0.8Mpa

|

|||

|

Power Voltage |

380V,50Hz 3P |

|||

|

Approx. Machine Weight |

17T |

21T |

17.5T |

21.5T |

Cylinder lifting system

Automatic sheet feeding

Able to work with double roll

Max.roll diameter:1200MM

Servo motor control

Aluminum alloy strip cooling

Automatic lubrication of the chain(PLC control)

Can stretch the sheet material

Oven size: Up and down 13 * 10 MM

Equipped with anti sheet falling sensor

Adopting German Elstein ceramic heater

Maximum forming depth:140 MM

4 pillar supports

Maximum Forming Layout:780*650 MM

Max. stroke:160 MM

Cylinder lock mold

Adopting a vacuum suction structure, each air tube is independently connected to the gas source to ensure that one product is not sucked in and affects other products.

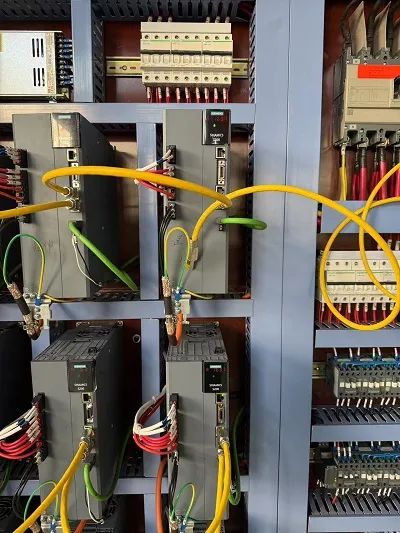

High quality electronic components ( SIEMENS, OMRON, SEW, SCHNEIDER )

High power cabinet air conditioner

Canada

Peru

Ecuador

Guyana

Ghana

Saudi Arabia

Egypt

Kenya

Dubai

Sri Lanka

Vietnam

Iraq

Bangladesh

India

Jordan

Nigeria

Pakistan

We are a professional plastic machinery provider in China.